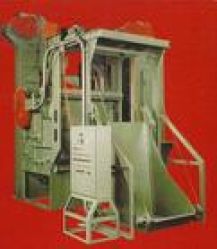

Full Auto Feed Apron Type Shot Blasting Machine

| Price : | $15000.00 |

| Quantity : | 10 () |

| Minimum Order : | 1 |

| Product Status : | New |

| Sample Available : | no |

| Payment Mode : |

Cash,Bank Transfer |

| Categories : | Machinery, Casting & Forging |

| Posted By : | Yancheng Fengte Machinery Co., Ltd |

Description

1

The parts to be blasted are placed in a bucket, and then automatically loaded into blasting machine through a lifter. Once blasting is accomplished parts are automatically out fed through vibration conveyor.

2 STEEL BALL COLLECTION SYSTEM:

The screw conveyor is equipped with a heavy grit sieving device for automatic exhaust.

3 An air operated steel ball separator, built on the lifter, fully separates steel balls from sand and dust, reducing, parts wear to a minimum.

| MODEL | Q-3210 |

| PROCESSING CAPACITY | 450kg |

| BLADE | 360 x 150 x 1 set |

| MOTOR | 20 HP x 4P x 1 set |

| CIRCULAR BELT | 900 x 980(W) |

| MOTOR | 2 HP x 4 P x 1 set |

| SCREW MOTOR | 1 HP x 4 P x 1 set |

| LIFTER | 260 x 460 x 4600(H) |

| MOTOR | 1 HP x 4 P x 1 set |

| DOOR | 1 HP x 4 P x brake x 1 set |

| INFEED TANK | 1 ton lifer x 1 set |

| VIBRATION CONVEYOR | 2 HP x 6 P x 1 set |

| AIR FLUSHING DUST COLLECTOR | 3 HP x 2 P x 1 set |

| DUST SEPARATOR MOTOR | 1/2 HP x 4 P x 1 set |

| TOTAL HORSEPOWER | 32 HP |

| NET WEIGHT | 5800 kg |

| OCCUPIED SPACE | 3980 x 2980 x4600 (H) |

|