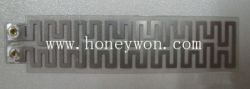

Pet Flexible Film Heater

| Price : | $1.00 |

| Quantity : | 1000000000 (piece) |

| Minimum Order : | 1 |

| Product Status : | New |

| Sample Available : | yes |

| Shipment Terms : | Negotiable |

| Payment Mode : |

T/T,cash |

| Categories : | Electrical & Electronics, Electrical Control System |

| Posted By : | Honeywon Silicone Products Co.,ltd |

Description

PET flexible heaters, or FILM heaters, are ideal for applications with space and weight limitations, or

where the heater will be exposed to vacuum, oil, or chemicals. These thin, flexible heaters are rugged,

accurate and reliable.

Benefits of PET Heaters:

• Thin, lightweight heaters allow you to apply heat where it’s needed, reducing operating costs

• Etched-foil heating technology provides fast and efficient thermal transfer for increased throughput

• Customized options (i.e. SMT components, flex leads and connectors) offer turnkey solutions to drastically reduce assembly time and increase productivity

• Custom profiling gives uniform thermal performance of the heating output to improve processing yields and productivity

Technical specifications:

Temperature range: -50~100C, Upper limit with 0.003 inch (0.08mm) foil backing is 100C.

Material:0.002 inch PET/0.05mm

Resistance tolerance: +/-10%

Dielectric strength: 1000VRMS

Minimum bend radius: 0.03 inch (0.8mm)

Lead wire: PTFE insulated, stranded,

Currency capacity (based on 100C max ambient temperature):

AWG 30-3.0 A; AWG 26-5.0 A; AWG 24-7.5 A; AWG 20-13.5 A.

Maximum thickness of heater: 0.012 inch/0.3mm

Standard thickness: 0.1~0.2mm

Configuration: PSA backing

Features of PET Heaters:

• FEP internal adhesive for use to 100°C (392°F)

• UL component recognition available

• Suitable for vacuum environments (NASA-RP-1061)

• NASA approved materials for space applications (S-311-P-079)

• Resistant to most chemicals: acids and solvents

• Radiation resistant to 10^6 rads (custom option)

• Very small sizes available

• Fluid immersible designs available (not standard)

Typical Applications

• Medical diagnostic instruments: Heat sample trays, cuvettes, reagent bottles, etc.

• Warm satellite components

• Protect aircraft electronic and mechanical devices against cold at high altitudes

• Stabilize optoelectronic components

• Test or simulate integrated circuits

• Enable cold weather operation of outdoor electronics such as card readers or LCDs

• Maintain constant temperature in analytic test equipment

where the heater will be exposed to vacuum, oil, or chemicals. These thin, flexible heaters are rugged,

accurate and reliable.

Benefits of PET Heaters:

• Thin, lightweight heaters allow you to apply heat where it’s needed, reducing operating costs

• Etched-foil heating technology provides fast and efficient thermal transfer for increased throughput

• Customized options (i.e. SMT components, flex leads and connectors) offer turnkey solutions to drastically reduce assembly time and increase productivity

• Custom profiling gives uniform thermal performance of the heating output to improve processing yields and productivity

Technical specifications:

Temperature range: -50~100C, Upper limit with 0.003 inch (0.08mm) foil backing is 100C.

Material:0.002 inch PET/0.05mm

Resistance tolerance: +/-10%

Dielectric strength: 1000VRMS

Minimum bend radius: 0.03 inch (0.8mm)

Lead wire: PTFE insulated, stranded,

Currency capacity (based on 100C max ambient temperature):

AWG 30-3.0 A; AWG 26-5.0 A; AWG 24-7.5 A; AWG 20-13.5 A.

Maximum thickness of heater: 0.012 inch/0.3mm

Standard thickness: 0.1~0.2mm

Configuration: PSA backing

Features of PET Heaters:

• FEP internal adhesive for use to 100°C (392°F)

• UL component recognition available

• Suitable for vacuum environments (NASA-RP-1061)

• NASA approved materials for space applications (S-311-P-079)

• Resistant to most chemicals: acids and solvents

• Radiation resistant to 10^6 rads (custom option)

• Very small sizes available

• Fluid immersible designs available (not standard)

Typical Applications

• Medical diagnostic instruments: Heat sample trays, cuvettes, reagent bottles, etc.

• Warm satellite components

• Protect aircraft electronic and mechanical devices against cold at high altitudes

• Stabilize optoelectronic components

• Test or simulate integrated circuits

• Enable cold weather operation of outdoor electronics such as card readers or LCDs

• Maintain constant temperature in analytic test equipment

|