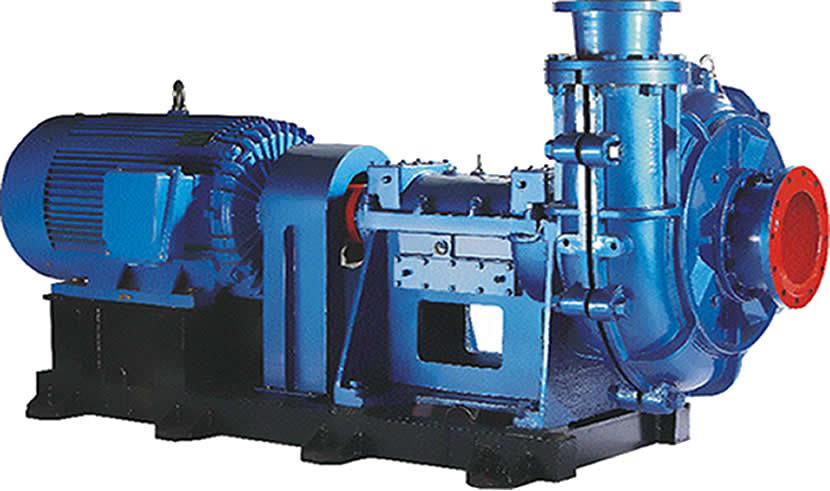

Ytz Series Slurry Pump

| Price : | Price Negotiable |

| Quantity : | 1000 () |

| Minimum Order : | 1 |

| Product Status : | New |

| Sample Available : | yes |

| Payment Mode : |

Bank Transfer,L/C |

| Categories : | Machinery, Pump & Vacuum Equipment, Centrifugal Pump |

| Posted By : | Shijiazhuang Ruite Pump Co.,ltd |

Description

YTZ SERIES SLURRY PUMP

FEATURE:

1、 Double Volite casing pump (Double metal structure or outer metal casing, rubber linning ) and single volute casing pump (single casing, metal structure)

2、 Pump outlet can be spaced by 45。and installed by rotating eight different angles as per requirement.

3、 Advanced structure

4、 energy-efficient

Application:

With its advanced characteristics, hydro mechanical designing, anti-abrasion ability and no leakage, YTZ series pump is approved by all the clients.It is mainly used in the industries of non-ferrous metal, mining, coal, and electric power etc.When handling abrasive and corrosive liquid containing solid particles, the concentration percentage by weight should be Cw ≤65% and medium temperature T≤120℃.

Structure Features: Excellent in anti-abrasion and erosion

Multi-element alloy cast iron and optimum hydraulic design specially developed for conditions of strong abrasiveness improves greatly the anti-abrasion performance of YTZ series slurry pumps.

No leaking. Distinctive composite mechanical seal ensures absolutely no leaking and long service life.

High efficiency

Advanced hydraulic model, medium frequency smelting and expendable pattern casting (EPC) process ensure that YTZ series slurry pump is of 3-5% higher efficiency than other pumps of similar type.

Convenient installation and maintenance

YTZ series slurry pump is double-case single-stage single-suction horizontal headstock pump. The double case is of vertical middle open. The outlet can be located at 8 different points rotating with 45°intervals. The bearing chamber is of grease lubrication and thin oil lubrication alternative. Convenient pump check and maintenance are ensured with horizontal middle open headstock which facilitates easy removal of the bearing parts inside.

Rotation direction: The pump rotor runs clockwise when looking from the drive end.

Driving mode: This series slurry pump can adopt direct connection DC, belt driving (parallel belt driving CR, CL; backing belt driving CV; tail belt driving ZV), hydraulic force driving and frequency control driving, etc.

Materials of pump main parts

| Parts | Material |

| Pump body; pump cover | HT250 |

| QT405-10 QT500-7 | |

| ZG230-450 ZG270-500 | |

| Impeller; sleeve; shield | KT49 |

| Cast stainless steel | |

| CD-4MC u | |

| Auxiliary impeller; pressure reducing cover | HT250 |

| QT450-10 QT500-7 | |

| Cast stainless steel | |

| Shaft | 45 |

| 40Cr | |

| 0 Cr17Ni12Mo(316) | |

| Shaft sleeve | KT49 |

| 0 Cr17Ni12Mo2Ti | |

| CD-4MCu(GX2Gr25Ni6Mo3Cu3N) | |

| Bearing housing; bracket | HT250 |

Scope of Supply Pump, base (common base or pump base), matching prime mover (motor or diesel engine), special tools for driving parts, start device (selective)

To Order

Please note in detail when placing an order:

Medium condition: flow rate, lift, viscosity, specific gravity, particle size, working temperature, PH, suction mode, driving mode, etc.;

Matching motor: specification, main technical parameter, protection grade, manufacturer, etc.;

Others: pump spare parts, speed-regulating device needed or not;

Other special requirements.

|

|