Sell Yuanying Honeycomb Ceramics, Foamed Ceramics

| Price : | $1500.00 |

| Quantity : | 100 (cubic meter) |

| Minimum Order : | 5 |

| Product Status : | New |

| Sample Available : | yes |

| Shipment Terms : | fob,cfr,cif,Negotiable |

| Payment Mode : |

T/T,L/C,cash,WesternUnion |

| Categories : | Chemicals, Other Chemicals |

| Posted By : | Yuanying Industry Limited |

Description

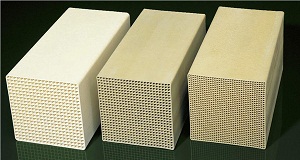

Honeycomb Ceramics

Ceramic honeycomb has many advantages such as small size, light weight, large surface area, high refractoriness, high heat capacity, low air flow resistance loss, and so on. Compared with regenerative ball, honeycomb ceramic is more difficult to plug straight airflow path; honeycomb ceramic regenerative chamber volume also significantly reduced, a sufficient amount of burners can be arranged to meet the needs of the thermal load. Honeycomb ceramic can guarantee temperature uniformity, rapid heat transfer, low oxygen combustion, significantly reducing oxidation loss and NOx gases generated, significantly improving environmental protection and energy-saving effect.

Honeycomb ceramic regenerators developed by Yuanying avoid the common shortcomings of honeycomb ceramic regenerator on the market, very suitable for used under HTAC conditions. It has high temperature resistance, good thermal shock resistance, corrosion resistance, high strength, big heat storage capacity, good thermal conductivity and other significant advantages, greatly improved energy efficiency and service life.

Yuanying ceramic honeycomb has good thermal stability, good crack resistance, low pressure loss, low thermal expansion coefficient, high water absorption, good corrosion resistance, big surface area, and so on. It is very suitable for used as heat storage material in regenerative incinerator, and has been widely used in RTO/RCO devices at home and abroad.

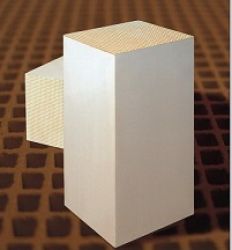

Foamed Ceramics

Yuanying foamed Ceramics filter has the characters of light, excellent heat resistant and chemical corrosion. With the distributing pores net structure, they are able to absorb the small waste, so the liquid metal can be molded safety. Yuanying Foamed Ceramics is widely used in the plant of steel, iron, copper and aluminum

|

|