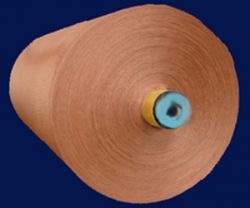

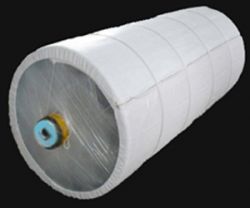

Nylon Tyre Cord Fabric

| Price : | Price Negotiable |

| Quantity : | 500000 (metric ton) |

| Minimum Order : | 20 |

| Product Status : | New |

| Sample Available : | yes |

| Shipment Terms : | fob,cfr,cif |

| Payment Mode : |

T/T,L/C,cash |

| Categories : | Textile, Industrial Textile |

| Posted By : | Weifang Senyu Trading Co., Ltd. |

Description

Brief introduction

Nylon 6 grey and dipped tyre cord fabrics having high strength, fatigue resistance, impact resistance, high adhesion characteristics, are mainly used as reinforcements of bias tyres:

1. Dipped tyre cord fabrics that made of multifid yarns are widely used to make auto tyres, agricultural machinery tyres and safety products such as air bags.

2. Dipped tyre cord fabrics that made of single twisting yarns are widely used to make motorcycle tyres, electric car tyres, bicycle tyres, and other moped tyres.

Specification:

We can offer nylon tyre cord fabrics such as 840D/1, 840D/2, 1260D/1, 1260D/2, 1260D/3, 1680D/1, 1680D/2, 1890D/2, etc.

Packing: Packed in rolls, using standard packing materials and methods. One 20' FCL container can hold 10 matric tons.

Payment terms: L/C at sight or T/T.

Specifications of Single Nylon Tyre Cord Fabric

| NO. | ITEMS | Unit | 930dtex1 | 1400dtex1 | 1870dtex1 |

| 1 | Breaking strength | N/end | ≥70 | ≥105 | ≥127 |

| 2 | Elongation at 44.1N | % |

|

| 8±1.0 |

| 3 | Elongation at 33.3N | % |

| 7.5±1.0 |

|

| 4 | Elongation at 22.6N | % | 7.5±1.0 |

|

|

| 5 | Adhesive strength | N/end | ≥49 | ≥64 | ≥78 |

| 6 | Diameter | MM | 0.32±0.03 | 0.43±0.03 | 0.50±0.03 |

| 7 | Twist | T/ 10cm | 21±1.5 | 19±1.5 | 19±1.5 |

| 8 | Unevenness of breaking strength≤ | % | ≤4.5 | ≤4.5 | ≤4.5 |

| 9 | Unevenness of breaking elongation≤ | % | ≤6.0 | ≤6.0 | ≤6.0 |

| 10 | Dip pick-up | % | 4.2±1.2 | 4.2±1.2 | 4.2±1.2 |

| 11 | Breaking elongation | % | 20±2 | 20±2 | 20±2 |

| 12 | Percentage of moisture | ≤ | ≤0.8 | ≤0.8 | ≤0.8 |

| 13 | Dry-hot shrinkage | ≤ | ≤4.0 | ≤4.0 | ≤4.0 |

Specifications of Dipped Nylon-6 Tyre Cord Fabric

| NO. | ITEMS | UNITE | 840D/1 | 840D/2 | 1260D/2 | 1260D/3 | 1680D/2 | 1890D/2 |

| 930 | 930 | 1400 | 1400 | 1870 | 2100 | |||

| 1 | Breaking Stength (min) | N/end ≥ | 67 | 132 | 205 | 305 | 270 | 305 |

| 2 | Elongation | % | 7.0 ± 1.0 |

|

|

|

|

|

| Elongation | % |

| 8.0 ± 1.0 |

|

|

|

| |

| Elongation | % |

|

| 8.5 ± 1.0 |

|

|

| |

| Elongation | % |

|

|

|

| 8.5 ± 1.0 |

| |

| Elongation | % |

|

|

| 9.0 ± 1.0 |

| 9.0 ± 1.0 | |

| 3 | Adhesion (H-test) (min) | N/Cm ≥ | 49 | 98 | 117 | 150 | 137 | 150 |

| 4 | Breaking strength difference (max) | ≤ % | 4 | 4 | 4 | 4 | 4 | 4 |

| 5 | Breaking elongation difference (max) | ≤ % | 6 | 6 | 6 | 6 | 6 | 6 |

| 6 | Dip pick up | % | 5.0 ± 1.2 | 4.5 ± 1 | 4.5 ± 1 | 4.5 ± 1 | 4.5 ± 1 | 4.5 ± 1 |

| 7 | Breaking elongation | % | 20 ± 2 | 22 ± 2 | 23 ± 2 | 23 ± 2 | 23 ± 2 | 23 ± 2 |

| 8 | Diameter | mm | 0.32 ± 0.03 | 0.55 ± 0.04 | 0.65 ± 0.04 | 0.78 ± 0.04 | 0.75 ± 0.04 | 0.78 ± 0.04 |

| 9 | Twist Single twist (Z) | T/ 10cm | 21 ± 1.5 | 46 ± 1.5 | 38 ± 1.5 | 32 ± 1.5 | 33 ± 1.5 | 32 ± 1.5 |

| Ply twist (S) |

| / | 46 ± 1.5 | 38 ± 1.5 | 32 ± 1.5 | 33 ± 1.5 | 32 ± 1.5 | |

| 10 | Hot air shrinkage | ≤ % | 6.0 | 7.0 | 7.0 | 7.0 | 7.0 | 7.0 |

Note: All the above products can be produced according to customers' requirements.

|

|