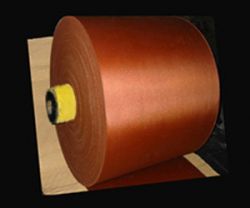

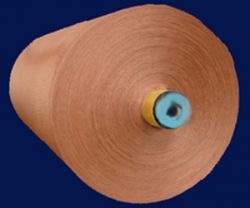

Ep Belting Fabric

| Price : | Price Negotiable |

| Quantity : | 200000 (metric ton) |

| Minimum Order : | 20 |

| Product Status : | New |

| Sample Available : | yes |

| Shipment Terms : | fob,cfr,cif |

| Payment Mode : |

T/T,L/C,cash |

| Categories : | Textile, Industrial Textile |

| Posted By : | Weifang Senyu Trading Co., Ltd. |

Description

Brief introduction

EP belting fabric in various specifications, widely used in traditional rubber industry. This kind of belting fabric has such advantages as small wear, high strength and tear resistance, etc. It is an ideal reinforcement material used for the framework material of conveyor belt.

Specification: We can offer kinds of grade EP belting fabric such as EP80, EP100, EP125, EP150, EP160, EP200, EP250, EP300, EP315, EP350, EP400, EP450, EP500, EP550, EP600, etc.

Packing: Commonly packed in rolls, 10MT per 20 foot container.

Payment terms: L/C at Sight or T/T payment.

Specifications of Dipped EP Belting Fabric (1)

| NO. | ITEM | UNIT | EP-80 | EP-100 | EP-125 | EP-150 | EP-160 | |||||

| Warp | Weft | Warp | Weft | Warp | Weft | Warp | Weft | Warp | Weft | |||

| 1 | Ave breaking strength | N/mm | 105 | 45 | 132 | 50 | 160 | 65 | 200 | 70 | 210 | 70 |

| 2 | Elongation at 10% load | % | 1.5 |

| 1.5 |

| 1.5 |

| 1.5 |

| 1.5 |

|

| 3 | Breaking Elongation | % | ≥ 14 | ≤ 60 | ≥ 14 | ≤ 45 | ≥ 14 | ≤ 45 | ≥ 14 | ≤ 45 | ≥ 14 | ≤ 45 |

| 4 | Hot air shrinkage 150 ℃ x30min | % | 5 | 0.5 | 5 | 0.5 | 5 | 0.5 | 5 | 0.5 | 5 | 0.5 |

| 5 | Adhesion | N/mm | 7.8 | 7.8 | 7.8 | 7.8 | 7.8 | |||||

| 6 | Weight per square metre | g/㎡ | 310±12 | 365±15 | 440±20 | 540±20 | 560±20 | |||||

| 7 | Thickness | mm | 0.49±0.05 | 0.55±0.05 | 0.60±0.05 | 0.70±0.05 | 0.75±0.05 | |||||

| 8 | Width | mm | 800-2400 | 800-2500 | 800-2500 | 800-2500 | 800-2500 | |||||

| 9 | Piece length | m | 400-1200 | 400-1200 | 400-1200 | 400-1200 | 300-1200 | |||||

Specifications of Dipped EP Belting Fabric (2)

| NO. | ITEM | UNIT | EP-200 | EP-250 | EP-300 | EP-315 | EP-350 | |||||

| Warp | Weft | Warp | Weft | Warp | Warp | Warp | Weft | Warp | Weft | |||

| 1 | Ave breaking strength | N/mm | 240 | 80 | 310 | 90 | 340 | 90 | 370 | 90 | 390 | 90 |

| 2 | Elongation at 10% load | % | 1.5 |

| 1.5 |

| 1.5 |

| 1.5 |

| 1.5 |

|

| 3 | Breaking Elongation | % | ≥ 14 | ≤ 45 | ≥ 14 | ≤ 45 | ≥ 14 | ≤ 45 | ≥ 14 | ≤ 45 | ≥ 14 | ≤ 45 |

| 4 | Hot air shrinkage 150 ℃ x30min | % | 5 | 0.5 | 5 | 0.5 | 5 | 0.5 | 5 | 0.5 | 5 | 0.5 |

| 5 | Adhesion | Nmm | 7.8 | 7.8 | 7.8 | 7.8 | 7.8 | |||||

| 6 | Weight per square metre | g/㎡ | 640±25 | 790±30 | 880±30 | 920±30 | 1070±35 | |||||

| 7 | Thickness | mm | 0.85±0.05 | 1.07±0.10 | 1.15±0.12 | 1.20±0.12 | 1.26±0.15 | |||||

| 8 | Width | mm | 800-2500 | 800-2500 | 800-2500 | 800-2500 +0/-20 | 800-2500 +0/-20 | |||||

| 9 | Piece length | m | 300-1200 | 200-1000 +/-20 | 200-800 | 200-800 | 200-800 | |||||

Specifications of Dipped EP Belting Fabric (3) NO. ITEM UNIT EP-400 EP-450 EP-500 EP-550 EP-600 Warp Weft Warp Weft Warp Warp Warp Weft Warp Weft 1 Ave breaking strength N/mm 450 90 500 100 570 100 620 110 670 120 2 Elongation at 10% load % 1.5 1.5 1.5 1.5 1.5 3 Breaking Elongation % ≥ 14 ≤ 45 ≥ 14 ≤ 45 ≥ 14 ≤ 45 ≥ 14 ≤ 45 ≥ 14 ≤ 45 4 Hot air shrinkage 150 ℃ x30min % 5 0.5 5 0.5 5 0.5 5 0.5 5 0.5 5 Adhesion Nmm 7.8 7.8 7.8 7.8 7.8 6 Weight per square metre g/㎡ 1220±40 1340±35 1450±40 1750±40 2070±50 7 Thickness mm 1.57±0.15 1.70±0.15 1.80±0.15 2.0±0.15 2.43±0.15 8 Width mm 800-2500 800-2500 800-2500 800-2500 +0/-20 800-2500 +0/-20 9 Piece length m 200-800+/-20 200-600 200-500 200-400 200-400

(min)

(max)

(max)

(max)

(min)

+0/-20

+0/-20

+0/-20

+/-20

+/-20

+/-20

+/-20

Note: All the above products can be produced according to customers' requirements.

|

|